Productbeschrijving:

Het product Stalen Ruimteframes biedt een uitzonderlijke structurele oplossing die sterkte, veelzijdigheid en kosteneffectiviteit combineert, waardoor het een ideale keuze is voor een breed scala aan bouwprojecten. Bekend om zijn lage kosten en hoge prestaties, wordt dit product vooral gewaardeerd in toepassingen zoals de constructie van Ruimteframes voor Tentoonstellingshallen, waar zowel duurzaamheid als esthetische flexibiliteit van cruciaal belang zijn.

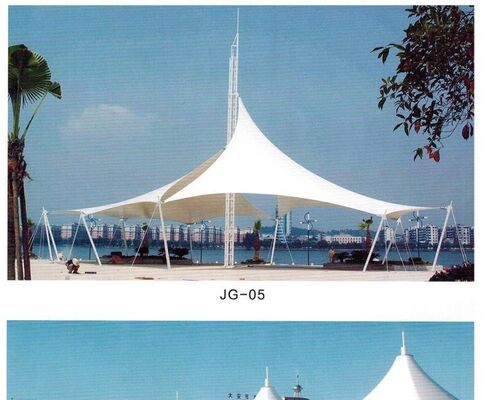

Een van de bepalende kenmerken van de Stalen Ruimteframes is hun uitstekende windbestendigheid. Ontworpen om barre omgevingsomstandigheden te weerstaan, bieden deze structuren superieure stabiliteit en veiligheid, zelfs bij extreme windbelastingen. Dit maakt ze bijzonder geschikt voor overkappingssystemen met grote overspanningen, zoals de installatie van Stalen Ruimteframe Daken, waar het behoud van structurele integriteit cruciaal is.

De ontwerpflexibiliteit van de Stalen Ruimteframes is een ander belangrijk voordeel. Deze frames kunnen worden aangepast om te voldoen aan een verscheidenheid aan architectonische en technische eisen, waardoor innovatieve en unieke ontwerpen mogelijk zijn zonder afbreuk te doen aan sterkte of veiligheid. Of het project nu gebogen vormen, complexe geometrieën of uitgestrekte open ruimtes vereist, de flexibele ontwerpmogelijkheden van de Stalen Ruimteframes voldoen gemakkelijk aan deze behoeften.

Wat betreft de constructiemethoden bieden de Stalen Ruimteframes meerdere verbindingsopties, waaronder bout- en lasverbindingen. Deze dubbele verbindingsmogelijkheid verbetert zowel het montagegemak als de algehele structurele stijfheid. Boutverbindingen zorgen voor een snellere installatie en eenvoudiger onderhoud of aanpassingen, terwijl lasverbindingen permanente, robuuste verbindingen bieden die bijdragen aan de duurzaamheid van het frame op lange termijn. De keuze tussen bout- en lasverbindingen zorgt ervoor dat bouwers het bouwproces kunnen optimaliseren op basis van specifieke projectvereisten.

De kernstructuur van het product is het ruimteframe zelf, een driedimensionaal raamwerk dat is samengesteld uit onderling verbonden stalen elementen die in een geometrisch patroon zijn gerangschikt. Deze structuur verdeelt de belastingen efficiënt over het gehele raamwerk, waardoor het materiaalgebruik wordt geminimaliseerd en de sterkte en stabiliteit worden gemaximaliseerd. Het ruimteframeontwerp is bijzonder effectief bij het overspannen van grote oppervlakken zonder de noodzaak van interne ondersteunende kolommen, waardoor het een voorkeurskeuze is voor Ruimteframe-projecten voor Tentoonstellingshallen waar een onbelemmerde binnenruimte essentieel is.

Een ander belangrijk kenmerk van deze Stalen Ruimteframes is de beschikbaarheid van gegalvaniseerde stalen opties. De variant Gegalvaniseerd Stalen Ruimteframe biedt een verbeterde corrosiebestendigheid, waardoor de levensduur van de structuur in buiten- of vochtige omgevingen wordt verlengd. Deze beschermende coating zorgt ervoor dat het staal in de loop van de tijd robuust en visueel aantrekkelijk blijft, waardoor de onderhoudskosten worden verlaagd en de algehele waarde wordt verhoogd.

Over het algemeen combineert het product Stalen Ruimteframes lage kosten met hoge prestaties en biedt het een flexibele ontwerpoplossing die voldoet aan de eisen van de moderne bouw. De hoge windbestendigheid, veelzijdige verbindingsmethoden en innovatieve ruimteframestructuur maken het een uitstekende keuze voor projecten variërend van grote tentoonstellingshallen tot commerciële daksystemen. De toevoeging van gegalvaniseerde stalen opties verbetert de duurzaamheid en levensduur verder, waardoor de structuur jarenlang betrouwbaar en aantrekkelijk blijft.

Kortom, of u nu een Ruimteframe voor een Tentoonstellingshal wilt bouwen, een Stalen Ruimteframe Dak wilt installeren of de voordelen van een Gegalvaniseerd Stalen Ruimteframe wilt benutten, dit product levert uitzonderlijke waarde en prestaties. De combinatie van betaalbaarheid, sterkte en ontwerpaanpassingsvermogen maakt het een opvallende oplossing op het gebied van structurele stalen raamwerken.

Kenmerken:

-

Productnaam: Stalen Ruimteframes

-

Afmetingen: Aangepast om te voldoen aan projectvereisten

-

Materiaal: Hoogwaardig Q235 / Q355 staal

-

Type: Ruimtelijke Stalen Structuur, ideaal voor diverse toepassingen

-

Toepassingen: Geschikt voor constructies van Kolenschuur / Cementloods Ruimteframes

-

Onderhoud: Weinig onderhoud vereist

-

Kosten: Lage kosten, biedt uitstekende waarde

-

Seismische Weerstand: Hoge seismische weerstand voor verbeterde veiligheid

Technische parameters:

|

Verbinding

|

Bout, Gelast

|

|

Installatie

|

Gemakkelijk

|

|

Onderhoud

|

Laag

|

|

Ontwerp

|

Flexibel

|

|

Seismische Weerstand

|

Hoog

|

|

Materiaal

|

Staal

|

|

Oppervlaktebehandeling

|

Gegalvaniseerd, Schilderen, Poedercoaten

|

|

Draagvermogen

|

Hoog

|

|

Windbestendigheid

|

Hoog

|

|

Structuur

|

Ruimteframe

|

Toepassingen:

De Stalen Ruimteframes, modelnummer 50000 van het gerenommeerde merk Lichtgewicht Stalen Frame Constructie, afkomstig uit Jiangsu, zijn ontworpen om te voldoen aan een breed scala aan toepassingsmogelijkheden en scenario's. Deze ruimteframe dakconstructies zijn ideaal voor grootschalige architectuurprojecten die zowel sterkte als esthetische aantrekkingskracht vereisen. Vanwege hun hoge draagvermogen en lange duurzaamheid worden ze vaak gebruikt in kritieke infrastructuursettings zoals treinstations en luchthaventerminals, waar veiligheid en uithoudingsvermogen van het grootste belang zijn.

Een van de belangrijkste toepassingsmogelijkheden voor deze stalen ruimteframes is de constructie van Ruimteframes voor Treinstations. De veeleisende omgeving van treinstations, die zwaar voetverkeer en dynamische belastingen van treinen ervaren, vereist een structurele oplossing die niet alleen sterk is, maar ook flexibel in ontwerp. Met de flexibele ontwerpeigenschappen die inherent zijn aan dit product, kunnen architecten en ingenieurs innovatieve en visueel opvallende dakconstructies creëren die grote oppervlakken kunnen overspannen zonder de noodzaak van talrijke steunkolommen, waardoor zowel de functionaliteit als de passagierservaring worden verbeterd.

Evenzo profiteren Ruimteframes voor Luchthaventerminals enorm van het gebruik van deze stalen ruimteframes. Luchthavens vereisen uitgestrekte, open binnenruimtes om grote aantallen reizigers en complexe operationele vereisten te kunnen accommoderen. Het hoge draagvermogen zorgt ervoor dat deze structuren uitgebreide daksystemen kunnen ondersteunen, inclusief geïntegreerde verlichting, HVAC-systemen en andere nutsvoorzieningen, zonder afbreuk te doen aan de structurele integriteit. Bovendien maakt de onderhoudsarme aard van deze stalen frames ze een economische keuze voor luchthavenautoriteiten, waardoor de operationele kosten op lange termijn worden verlaagd en tegelijkertijd de veiligheids- en prestatienormen worden gehandhaafd.

Naast vervoersknooppunten zijn deze stalen ruimteframes ook geschikt voor sportarena's, tentoonstellingshallen, commerciële gebouwen en industriële magazijnen. Hun stalen materiaalsamenstelling garandeert robuustheid en weerstand tegen omgevingsfactoren, waardoor een lange levensduur wordt gewaarborgd. De lichtgewicht aard van het gebruikte staal vermindert het totale gewicht van de constructie aanzienlijk, wat snellere bouwtijden en lagere funderingskosten mogelijk maakt.

Kortom, de Stalen Ruimteframes model 50000 van Lichtgewicht Stalen Frame Constructie bieden een veelzijdige en betrouwbare oplossing voor diverse structurele behoeften. Hun toepassing in ruimteframe dakconstructies, met name in treinstations en luchthaventerminals, benadrukt hun vermogen om flexibiliteit in ontwerp te combineren met superieure sterkte en levensduur, waardoor ze een uitstekende keuze zijn voor moderne architectuur- en engineeringprojecten.

Maatwerk:

Ons merk voor lichtgewicht stalen frameconstructie biedt premium Stalen Ruimteframe Dakoplossingen, ontworpen voor hoge prestaties en duurzaamheid. Modelnummer 50000 vertegenwoordigt ons geavanceerde Industriële Magazijn Ruimteframe, vakkundig vervaardigd in Jiangsu om aan strenge normen te voldoen. Met een flexibel ontwerp zorgt dit ruimteframe voor een uitstekende seismische weerstand en hoge windbestendigheid, waardoor het ideaal is voor uitdagende omgevingen. De structuur maakt gebruik van hoogwaardige Q235 / Q355 Stalen Ruimteframe materialen, die een uitzonderlijk draagvermogen en structurele integriteit bieden voor een breed scala aan industriële toepassingen.

Ondersteuning en diensten:

Onze Stalen Ruimteframes zijn ontworpen om superieure sterkte, duurzaamheid en architectonische veelzijdigheid te bieden voor een breed scala aan bouwtoepassingen. Om optimale prestaties en een lange levensduur te garanderen, bieden we uitgebreide technische ondersteuning en diensten die zijn afgestemd op uw projectbehoeften.

Ons technische ondersteuningsteam staat klaar om te helpen met ontwerpoptimalisatie, structurele analyse en integratie van de stalen ruimteframes in uw bouwsysteem. We bieden gedetailleerde installatierichtlijnen, inclusief stapsgewijze procedures, veiligheidsprotocollen en aanbevolen gereedschappen om een efficiënte en nauwkeurige montage ter plaatse te vergemakkelijken.

Daarnaast bieden we maatwerk fabricagediensten om te voldoen aan specifieke projectvereisten, zodat elk onderdeel wordt vervaardigd volgens precieze specificaties en kwaliteitsnormen. Onze ingenieurs kunnen samenwerken met uw ontwerpteam om op maat gemaakte oplossingen te ontwikkelen die zowel de esthetiek als de functionaliteit verbeteren.

Voor onderhoud en inspectie geven we deskundig advies over routinematige controles en preventieve maatregelen om de integriteit van de stalen ruimteframes in de loop van de tijd te behouden. Ons team kan ook helpen bij het oplossen van problemen en het oplossen van eventuele problemen die zich kunnen voordoen tijdens de levenscyclus van het product.

We streven ernaar uitzonderlijke klantenservice en technische expertise te leveren om uw succesvolle implementatie van Stalen Ruimteframes in uw projecten te ondersteunen.

FAQ:

V1: Wat is de merknaam van de Stalen Ruimteframes?

A1: De merknaam van de Stalen Ruimteframes is Lichtgewicht Stalen Frame Constructie.

V2: Wat is het modelnummer van dit Stalen Ruimteframe?

A2: Het modelnummer van het Stalen Ruimteframe is 50000.

V3: Waar wordt het Stalen Ruimteframe vervaardigd?

A3: Het Stalen Ruimteframe wordt vervaardigd in Jiangsu, China.

V4: Wat zijn de belangrijkste toepassingen van de Stalen Ruimteframes?

A4: Stalen Ruimteframes worden vaak gebruikt in bouwprojecten voor daken, constructies met grote overspanningen en architecturale raamwerken vanwege hun sterkte en lichtgewicht eigenschappen.

V5: Hoe profiteert de lichtgewicht stalen frameconstructie bouwprojecten?

A5: Lichtgewicht stalen frameconstructie biedt voordelen zoals verminderde structurele belasting, snellere installatie, verbeterde duurzaamheid en verbeterde ontwerpflexibiliteit.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!